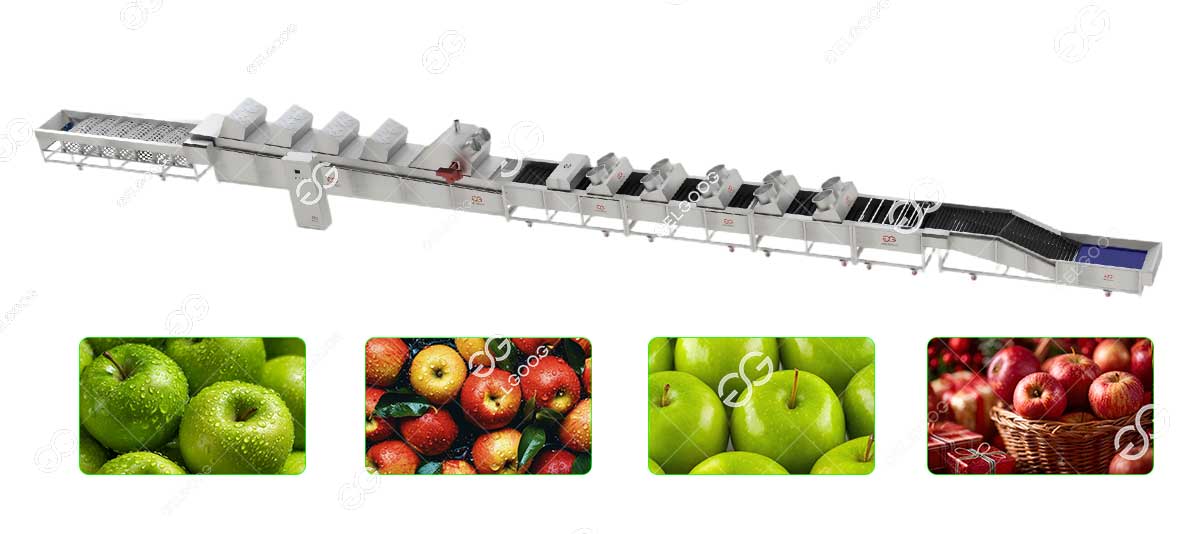

Apple Washing Waxing Drying Sorting Line

An apple fruit washing waxing line can improve the appearance quality of apples, effectively extend their shelf life, and increase their market value. The scientifically designed apple washing waxing sorting line operates stably and significantly reduces post-harvest losses. It is suitable for large-scale apple orchards, cooperatives, and professional fruit packaging plants. An apple fruit cleaning and waxing machine is key equipment for enhancing brand image and increasing profits.

Apple Fruit Washing Waxing Line Flow Chart

Feeding → Soaking → Washing → Air Drying → Waxing → Air Drying → Sorting → Packaging

- Feeding: Initial screening removes apples with obvious damage, rot, or deformities.

- Soaking: Initial cleaning of the apple surface. Soaking also softens surface stains, making subsequent cleaning more thorough.

- Washing: A bubble cleaning machine or a flat roller brush washing machine can be used to thoroughly remove dirt and pesticide residue from the apple skin.

- Air Drying: Drying the apple surface to ensure even wax adhesion.

- Waxing: Applying food-grade fruit wax evenly.

- Air Drying: Allowing the wax film to solidify quickly, ensuring an even wax layer.

- Sorting: Grading involves multi-dimensional inspection based on weight, diameter, appearance, and internal quality. Apples are then output in different grades.

- Packaging: Graded apples can be connected to an automatic meshing machine and labeling machine. They are then packaged according to grade into plastic crates, cartons, or premium gift boxes.

Fruit Cleaning And Waxing Machine

Apple Washing Machine

- Energy saving: The fruit cleaning and waxing machine is equipped with a water circulation system. The filtered water can be recycled, reducing water costs.

- Thorough cleaning: The apple washing machine cleans thoroughly without damaging the fruit peel.

Apple Waxing Machine

- High Quality: The apple waxing machine makes apples shinier while reducing moisture loss and extending shelf life.

- Low Waste: The apple waxing machine can precisely control the amount of wax applied via a PLC system, maximizing the efficiency of the fruit washing and waxing line.

Apple Sorting Machine

- Customization: Based on customer’s finished product requirements, we can provide weight grading machines, size grading machines, and photoelectric grading machines. All equipment can be customized for grading levels.

- High Quality: Photoelectric grading machines can grade apples based on appearance, weight, ripeness, and sweetness/tartness. Graded fruit is of high quality and has high market value.

Avocado Weight Grading Sorting Machine For Sale

Industrial Apple Pear Peach Washing Machine For Sale

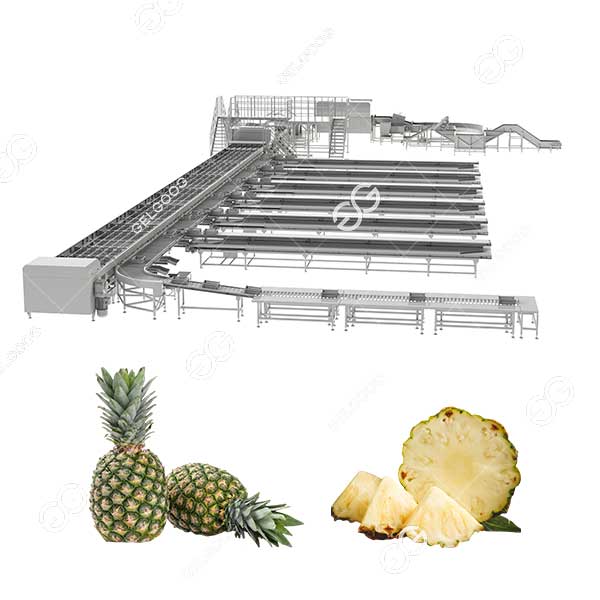

Pineapple Fruit Sorting Grading Machine 1-10 Tons Manufacturer

Apple Washing Waxing Sorting Line Advantages

- High Quality: The apple washing waxing sorting line produces high-end apples with uniform specifications and controllable quality. Sugar content grading meets the quality requirements of high-end supermarkets and chain brands. This opens up high-end sales channels and increases company revenue.

- Safety: The apple fruit cleaning and waxing machine is equipped with an emergency stop button. One-button shutdown ensures safe production.

- Hygiene: The apple fruit washing waxing line is made of food-grade stainless steel, making it sturdy and durable. Its modular design facilitates daily cleaning and maintenance, meeting world-class food safety requirements.

- Continuous Production: The core components of the apple washing waxing sorting line are made of corrosion-resistant materials, allowing for continuous production.

- Multi-functional: The apple washing waxing sorting line can also process citrus fruits, avocados, mangoes, pears, and other fruits, resulting in high equipment utilization.

- Automation: The fruit cleaning and waxing machine is highly automated, processing at least 1t of fruit per hour. It can replace manual grading and packaging, reducing labor costs and simplifying management.

Leave A Message For A Quote