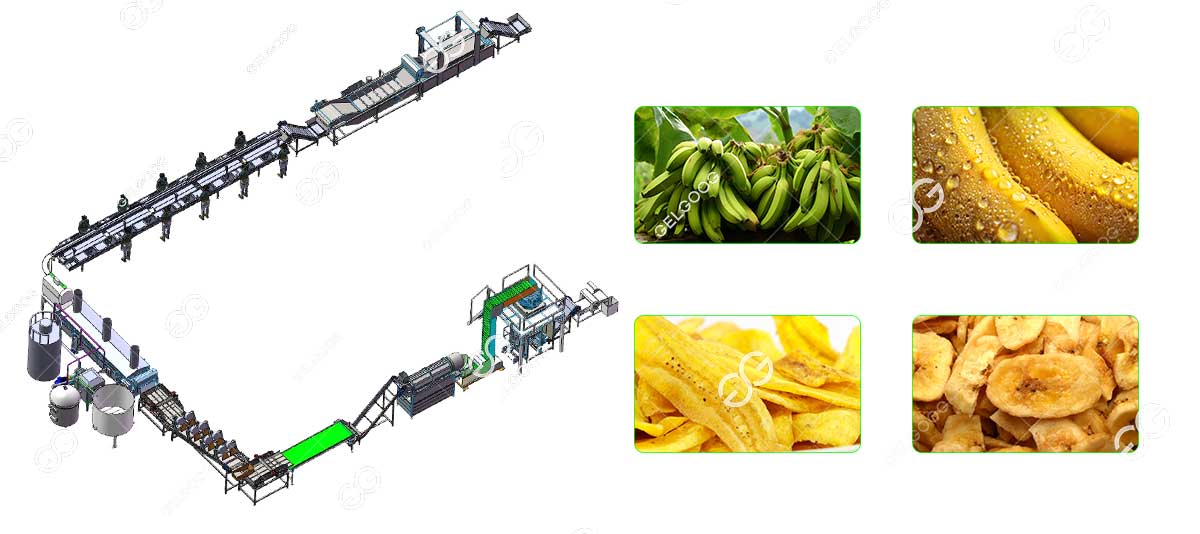

Automatic Banana Plantain Chips Production Processing Machine

Gelgoog banana chips processing line is a fully automated processing solution specifically designed for bananas and plantains.

The automatic banana chips making machine is designed for large-scale banana chip production. The thickness and shape of the slices are adjustable, and both long slices and whole slices can be made. The frying temperature can be precisely controlled, and the oil removal efficiency is high.The banana chips processing machine is made of food-grade stainless steel and meets HACCP/GMP standards. A secondary frying process can also be selected according to customer market demands.This makes the banana chips crispier and more durable.

The automatic banana chips making machine integrates multiple processes starting from banana raw material processing. It is the ideal choice for establishing a banana chip processing plant.

Plantain Chips Production Process Flow Chart

Washing → Peeling → Slicing → Blanching → Frying → Deoiling → Cooling → Sugar Soaking → Second Frying → Deoiling → Cooling → Seasoning → Packaging

- Washing: Select fresh bananas of moderate ripeness and wash them thoroughly.

- Slicing: Use a banana chips making machine to slice the peeled bananas into evenly thick chips.Different banana chips making machine are configured according to different customer needs.

- Blanching: Briefly blanch the plantain chips. This inactivates enzymes and protects the color, preventing browning during subsequent processing.

- Frying: Utilize a PLC intelligent control system. Fry the banana chips until crispy under precise temperature control.

- Deoiling: The plantain chips are conveyed to the deoiling zone. Excess surface oil is removed, resulting in a clean and non-greasy product.

- Sugar soaking: A sugar soaking process can be added according to customer requirements.

- Second Frying: A second frying process can be performed according to customer requirements. This makes the banana chips crispier and more durable.

- Cooling: Use a desiccant to rapidly cool the banana chips.

- Seasoning: Gelgoog has a processing laboratory that can provide you with a variety of seasoning techniques.

- Packaging: After cooling, the plantain chips can be packaged using a multihead weigher packing machine, pillow-type packaging or canning. Ensure the product is crispy and extend its shelf life.

Plantain Chips Production Process Machine

Banana Washing Machine

- Thorough Cleaning: Achieves high cleanliness without damaging the peel. Ensures every banana is as clean as new.

- Customizable: The washing speed and bubble size of the banana washing machine are adjustable. Customized cleaning is available based on the customer’s banana variety, ripeness, and origin.

- Water Saving: Wastewater can be reused after filtration. Reduces water costs.

Banana Chips Making Machine

- Easy to operate: Slice thickness is adjustable. Disassembly is simple, one person can complete the adjustment.

- Easy maintenance: The banana chips making machine is made of food-grade stainless steel. Safe and corrosion-resistant, easy to clean daily, and simple to maintain.

- Customizable: Long banana slices and round banana slices require different slicing machines. Different machines are configured according to the customer’s finished product requirements.

Plantain Chips Frying Machine

- Intelligent Control: Equipped with a PLC control system for intelligent temperature control during frying.Ensuring consistent plantain chip quality.

- Multiple Frying Methods: Choose between vacuum frying or a mixed oil-water fryer.

- Residue Collection: Built-in circulating filter.Collects residue generated during the plantain chip frying process.

Automatic Banana Plantain Chips Making Cutting Machine

Large Industrial Banana Washing Cleaning Machine

Plantain Chips Production Process Advantages

- High Efficiency: Compared to traditional manual slicing and frying, the automatic banana chip processing line significantly increases output.Reduces manpower and lowers labor costs.

- Consistent Quality: The banana chip making machine produces uniform chips, consistent frying, and thorough oil removal. Plantain chips are golden in color, crispy in texture, and uniform in size.

- Energy and Oil Saving: The frying equipment is equipped with an automatic filtration system.Extend frying oil life and reduce oil consumption.

- Customizable: The banana chip making machine is compatible with various blade sizes. The banana chip processing machine offers an optional double-frying process. Gelgog can configure packaging machines to meet customer needs. We provide customized solutions.

- Safe and Hygienic: The banana chip processing line is made of food-grade stainless steel. Easy to clean and meets export standards.

Leave A Message For A Quote