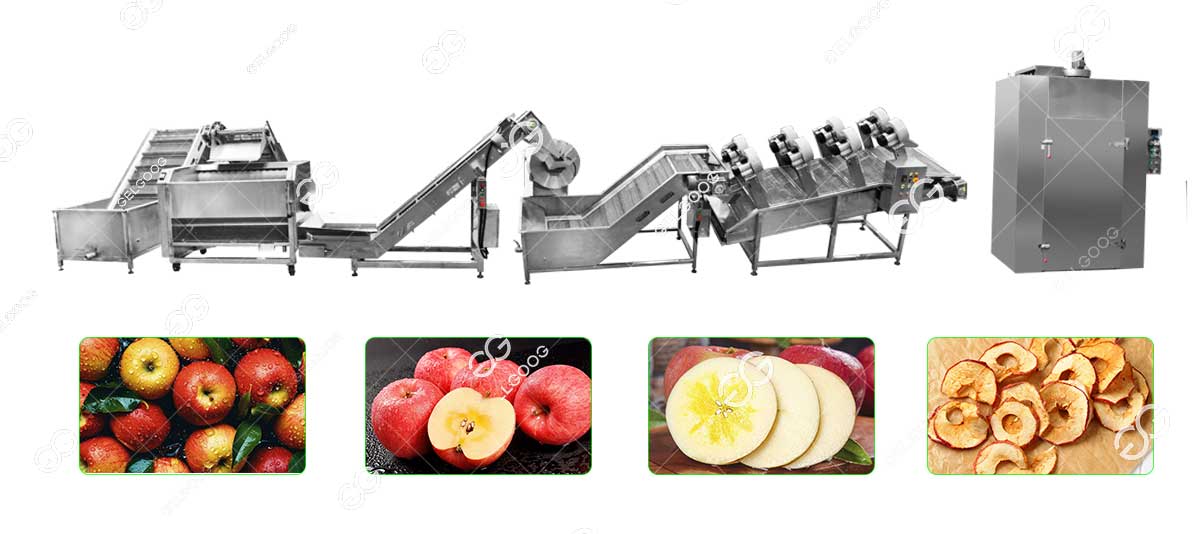

Automatic Dehydrated Apple Chips Making Line Machinery

Dehydrated apple chips processing machine can turns fresh apples into apple chips. It includes a washing machine, a slicing machine, a dehydrator, and a packaging machine. Automatic apple chips making machines produce dehydrated apple chips that are crisp, delicious, and highly nutritious. Dehydrated apple chips processing machine help fruit processing plants transform fresh apples into high-value-added dried fruit products, extending shelf life, reducing spoilage, and increasing economic benefits.

Dehydrated Apple Chips Processing Flow Chart

Feeding → Washing → Peeling and Core Removal → Slicing → Color Protection → Blanching → Cooling → Dehydration → Sorting → Packaging

- Feeding: Receive fresh apples. A color sorting machine can be used to remove rotten or damaged apples.

- Washing: Thoroughly wash the apple skin using an apple washing machine.

- Peel and pit: Optional. Gelgoog offers an apple peeling and coring machine. This is an option if you require high-quality dehydrated apple chips.

- Slicing: Use an automatic apple chips making machine to slice the apples into uniform chips.

- Color Protection/Blanching: Briefly immerse the sliced apples in a color protection solution to retain their natural yellow-white or pale yellow color. Blanching is for enzyme inactivation and color protection.

- Dehydration: The apple slices are dried at a low temperature using a heat pump drying machine.

- Sorting: Inspect dehydrated apple chips. Remove items with abnormal color, cracks, foreign objects, etc.

- Packaging: gelgoog offers various packaging options including vacuum packaging, sealed cans, and gift boxes.

Dehydrated Apple Chips Processing Machine

Apple Washing Machine

- Customization: Customers can choose between a bubble washing machine or a brush washing machine, depending on their needs. The washing intensity and duration can be adjusted freely.

- Thorough Cleaning: The apple washing machine effectively removes dirt, dust, and pesticide residues from the surface of apples.Ensuring hygiene and safety during subsequent processing.

Automatic Apple Chips Making Machine

- Uniformity: The automatic apple chips making machine slices uniformly with consistent thickness. This facilitates more even drying of the apple slices, improving the texture and crispness of the finished product. It also reduces drying energy consumption and lowers production costs.

- Multi-functional: The slicing thickness can be adjusted according to product requirements. It can slice apples, bananas, potatoes, etc., into slices ranging from 2-12mm thick.

Dehydrated Apple Chips Processing Machine

- Intelligent Control: The dehydrated apple chips processing machine employs segmented intelligent drying. It can control the temperature, humidity, airflow, and time during the drying process.This maximizes the preservation of the apple’s aroma, color, and nutritional value.

- High Quality: Hot air circulation technology ensures even heating of the apple chips. The consistent quality of each batch of apple chips enhances the company’s image.

Automatic Banana Plantain Chips Making Cutting Machine

Commercial Fruit Dehydrator Machine For Business

Industrial Apple Pear Peach Washing Machine For Sale

Apple Chips Machine Line Advantages

- Safety: The apple chips machine line is constructed entirely of food-grade stainless steel. Its modular design facilitates daily cleaning and maintenance, meeting world-class food safety requirements.

- High Quality: The dehydrated apple chips processing machine employs a segmented drying process. This preserves the natural color, flavor, and nutrients of the apples, resulting in products with excellent taste and appearance.

- Energy Saving: The apple chips machine line is equipped with a water circulation and hot air circulation system. This reduces water and heat loss, lowering production energy consumption.

- Versatile: The dehydrated apple chips processing machine allows for flexible adjustment of process parameters (such as washing intensity, slice thickness, and drying temperature and humidity). It can adapt to the production needs of banana chips, dried mango, dried onions, and other products.

- Automation: The dehydrated apple chips processing machine is highly automated, enabling continuous drying operations. This reduces labor costs and improves product consistency.

- Long Shelf Life: The automatic apple chips making machine effectively extends the shelf life of apples. It also reduces transportation costs and storage space. This enhances market adaptability and increases business revenue.

Leave A Message For A Quote