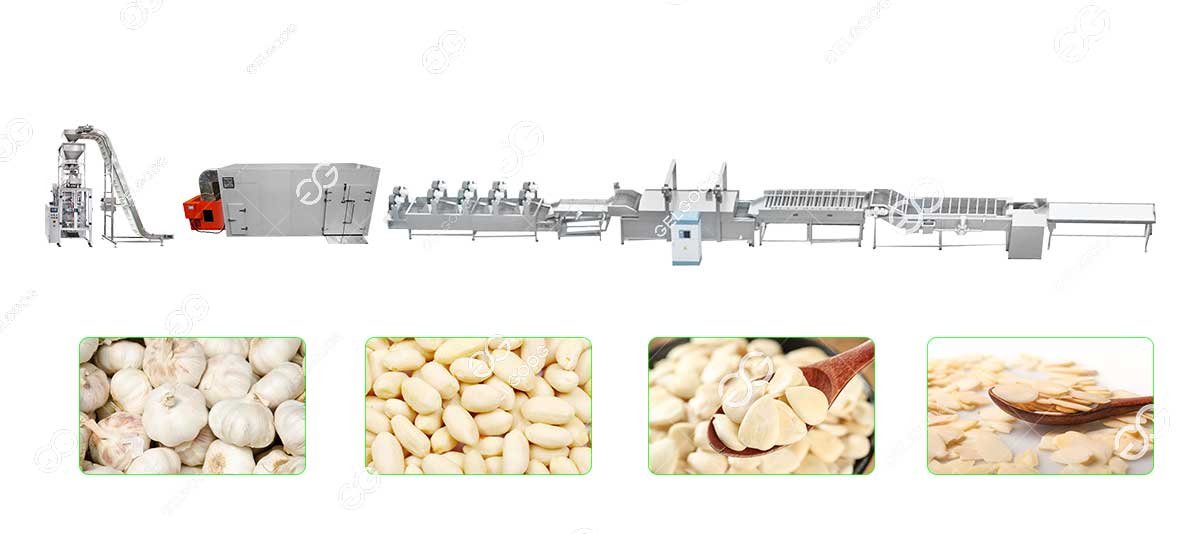

Dried Garlic Flakes Production Line 1T-2T/H

Dried garlic flakes are a crucial basic seasoning ingredient in the food industry. Gelgoog dried garlic flakes making machine produces high-quality garlic flakes with a bright white color and rich garlic flavor. We can customize a garlic flakes production line solution according to your factory layout and production capacity requirements.Gelgoog provide an efficient, energy-saving, and hygienic one-stop processing solution from raw garlic to high-quality dehydrated garlic flakes.

Garlic Flakes Production Line Flow Chart

Feeding → Clove Separation → Peeling → Sorting → Washing → Slicing → Blanching → Dewatering → Dehydration → Packaging

- Clove Separation: Separating whole garlic cloves into individual bulbs.

- Peeling: Removing the outer skin of the garlic using an air-blowing method.

- Sorting: Adding grading equipment according to customer needs. Selecting garlic that meets the requirements for subsequent processing.

- Washing: Gently washing the garlic to ensure cleanliness.

- Slicing: Slicing the garlic into evenly thick slices.

- Blanching: Reducing enzyme activity and preserving the natural color of the garlic.

- Dewatering: Removing surface moisture from the garlic.

- Dehydration: Evenly drying the internal moisture of the garlic.

- Packaging: Multiple packaging methods are available. Gelgoog provides a one-stop service including weighing, nitrogen/vacuum filling, sealing, and labeling.

Dried Garlic Flakes Making Machine

Garlic Peeling Machine

- Clean: The garlic peeling line is equipped with a skin collection system. This prevents garlic peels from flying everywhere and ensures factory hygiene.

- Thorough: The garlic peeling machine uses air to remove the peels thoroughly without damaging the garlic flesh.

Garlic Slicing Machine

- Continuity: The garlic flakes making machine can be connected to a garlic peeling and washing machine. Chopped garlic is directly fed into subsequent production lines, eliminating the need for manual transport.

- Durability: The garlic slicing machine is made of food-grade stainless steel. It is corrosion-resistant and has a long service life.

Garlic Dehydration Machine

- Energy-saving: Employs heat pump circulation and precise temperature and humidity control. The low-temperature, slow-drying process results in significant energy savings.

- Adjustable: The garlic drying process parameters are adjustable, adaptable to different garlic slice sizes.

Automatic Garlic Skin Peeling Machine Manufacturer

Fruit Bubble Washing Machine for Strawberries Blueberries Cherries

Vegetable Dehydration Drying Machine For Business

Garlic Flakes Production Line Advantages

- High Quality: The dried garlic flakes production line retains the natural aroma of garlic. Low-temperature drying technology preserves the active substances in the garlic. Dried garlic flakes have an excellent appearance and rich flavor.

- Intelligent Control: The dried garlic flakes making machine is equipped with a PLC control system and can be operated via touchscreen. Data can be recorded during processing, and alarms can be triggered promptly. This improves the convenience and production stability of the garlic flakes production line.

- Automation: The dried garlic flakes production line has a high degree of automation. It reduces manual intervention, ensuring stable production and convenient management.

- Wide Applications: Dried garlic flakes are an ideal raw material for compound seasonings, sauces, and other food products. Market demand is huge and stable.

- Extended Shelf Life: The moisture content of dried garlic flakes is reduced to below 5%. It can be safely stored for 1-2 years under normal temperature and moisture-proof conditions.

Leave A Message For A Quote