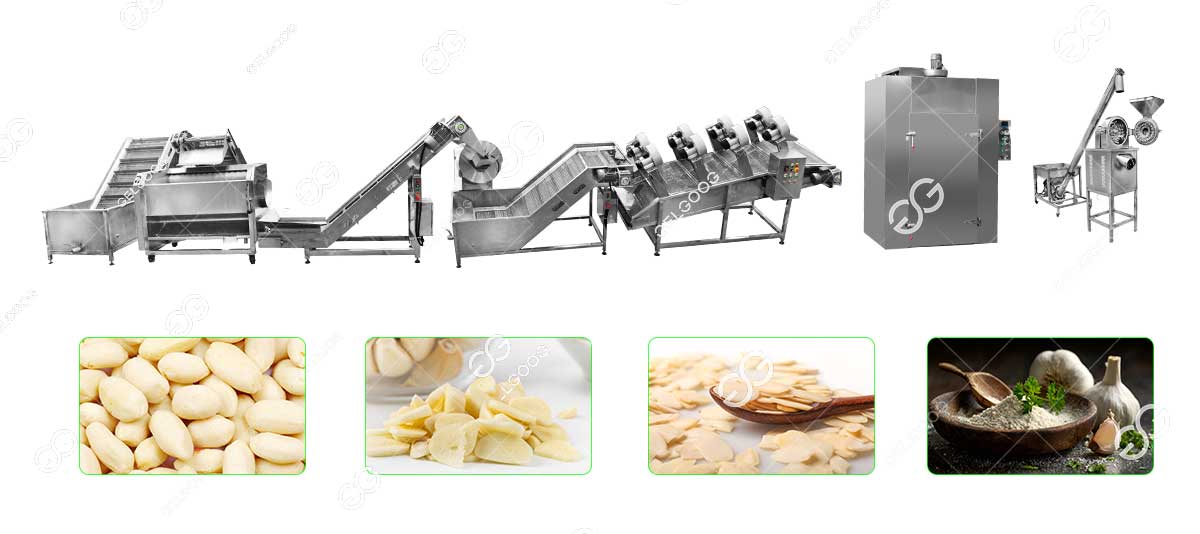

Garlic Powder Production Line Equipment Manufacture

Garlic powder is a high-value-added condiment that is convenient to use, has a stable flavor, and is easy to store. A garlic powder production line can produce high-quality garlic powder that is white in color, has a rich garlic aroma, and is finely powdered and free of impurities. Gelgoog provides you with a fully automated turnkey solution from raw garlic to high-quality commercial garlic powder.

Garlic Powder Processing Flow Chart

Feeding → Peeling → Sorting and Trimming → Slicing → Blanching → Dewatering → Dehydration → Cooling → Grinding → Vibrating Screening → Packaging

- Peeling: Automatic Garlic Peeling Production Line

- Slicing: Garlic cloves are fed into a slicing machine and cut into uniform slices or fragments. Prepares for subsequent drying.

- Blanching: Prevents enzymatic browning of garlic slices during drying and storage. Locks in the natural white color of the garlic slices.

- Dewatering: Removes surface moisture from the garlic. Reduces drying energy consumption and time.

- Drying: Gently removes internal moisture from the garlic slices at medium to low temperatures. Ultimately reduces the moisture content of the garlic slices to below 5%.

- Grinding: The garlic slices are ground into a uniform and fine garlic powder.

- Sieving: Separates large particles that do not meet the fineness requirements. These can be returned to the grinder for further processing.

- Packaging: Integrated quantitative, nitrogen-filled/vacuum-sealed, bagged, and labeled packaging, conforming to food industry standards.

Garlic Powder Processing Machine

Garlic Chips Cutting Machine

- High quality: The blade or crusher structure ensures uniform slice thickness and consistent particle size.

- High efficiency: It can process at least 100 kg of garlic per hour, far exceeding the efficiency of manual processing.

Dried Garlic Flakes Production Machine

- Intelligent Control: The garlic powder production line can control temperature and humidity.This ensures stable garlic drying quality and improves the final product quality.

- High Efficiency: Different stages have different evaporation curves. Garlic powder production equipment uses segmented drying to increase the drying rate. Precise temperature and humidity control is achieved. Segmented drying improves uniformity, and the drying temperature can be accurate to ±1℃. This ensures stable vegetable drying quality and improves the final product quality.

Garlic Powder Production Equipment

- Customization: Grinding fineness and sieves can be customized according to customer’s finished product requirements.

- Hygiene: The grinding process is fully enclosed to prevent dust from entering and ensure food safety.

Commercial Ginger Powder Grinding 80-200 Mesh Machine

Vegetable Cube Cutting Machine For Potato Carrot Oinon Dicer

Vegetable Dehydration Drying Machine For Business

Garlic Powder Processing Advantages

- Safety: The garlic powder production line is made of food-grade materials. Its quick-release structure facilitates cleaning. The automated, closed processing reduces the risk of cross-contamination.

- Environmentally Friendly: The garlic powder production equipment is equipped with a water circulation system. Zero emissions occur during the drying process, making it environmentally friendly.

- Intelligent Control: The garlic powder processing system features a PLC intelligent control system. The entire process is monitored, parameters are adjustable, and data is traceable. Remote monitoring and parameter adjustment are supported.

- Multi-functional: The garlic powder production line can also process ginger powder, moringa leaf powder, banana powder, and other products.

- Quality Assurance: We hold multiple technology patents. The processing effect of our garlic powder production equipment far surpasses similar products on the market. Top-tier garlic processing plants in the United States also use the Gelgoog garlic processing line.

Leave A Message For A Quote