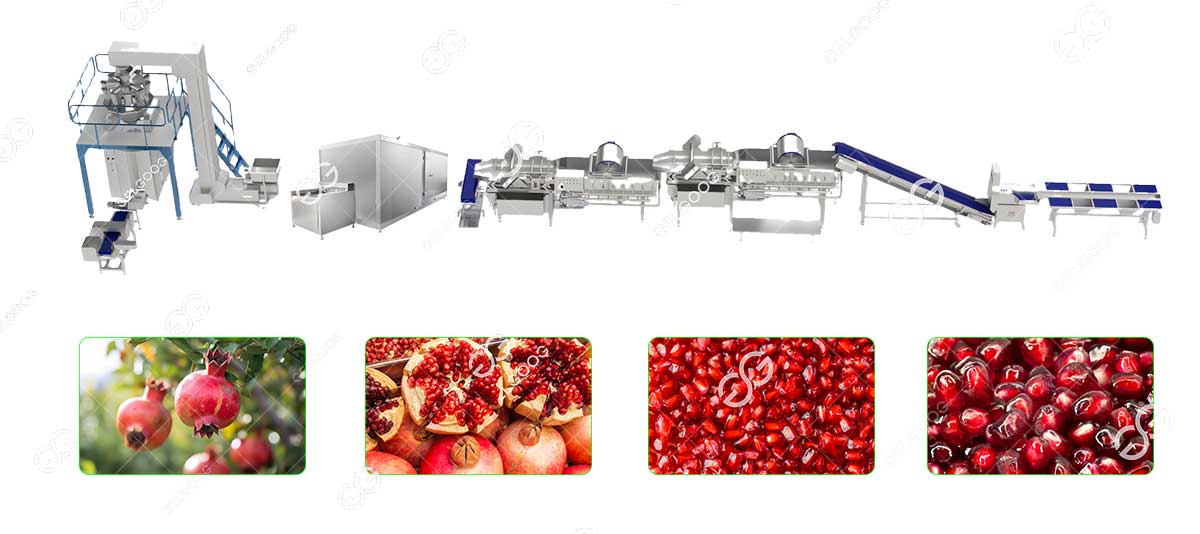

IQF Frozen Pomegranate Arils Processing Line

Pomegranate seeds have antioxidant nutritional value and a unique taste. Demand is growing in the high-end yogurt, salad, baked goods, and beverage markets. However, pomegranate arils are delicate and easily oxidized. How to completely peel and preserve the color of the arils is a challenge in processing.

Gelgoog IQF pomegranate arils processing line includes pomegranate washing, peeling, separation, rapid freezing, and packaging. The frozen pomegranate arils processing machine produces arils with high integrity, vibrant red color, and pure flavor. It is suitable for export-oriented fruit and vegetable processing plants, high-end frozen fruit suppliers, and large central kitchens.

IQF Pomegranate Arils Processing Flow Chart

Feeding → Washing → Peeling and Extraction → Vibration Removal → Washing → Water Removal → Quick Freezing → Packaging

- Feeding: AGV technology is used to transport pomegranates to the processing area. The pomegranates are first graded, and damaged or spoiled fruit is removed.

- Washing: Pomegranates are cleaned using a combination of air bubbles and spraying. This removes mud and impurities, ensuring the quality of subsequent processing.

- Peeling and Extraction: A pomegranate peeling machine is used to separate the pomegranate seeds.

- Removal: Small pieces of pomegranate peel and the white membrane are removed.

- Washing: The separated pomegranate seeds are washed again. This removes residual white membrane, fruit pulp, and moisture impurities.

- Water Removal: An air drying machine or vibration dehydration is used to remove surface moisture from the pomegranate seeds. This improves quick-freezing efficiency.

- IQF Quick Freezing: The cleaned and graded pomegranate seeds are fed into an IQF quick-freezing machine. The pomegranate seeds are quickly frozen into individual granules, preventing them from sticking together.

- Packaging: The multi-head scale packing machine uses an automatic weighing system. Quick-frozen pomegranate seeds are rapidly packaged according to customized specifications, such as 400g, 1kg, 10kg, etc.

Frozen Pomegranate Arils Processing Machine

Pomegranate Washing Machine

- Clean thoroughly: The pomegranate washing amchine gently removes surface dust and impurities using tumbling bubbles. This ensures the hygiene of raw materials during further processing.

- Water cycle: The pomegranate washing machine is equipped with a water circulation system. Impurities settle into the bottom filter tank. The water flows through the filter to remove impurities and can be recycled.

Pomegranate Seed Extraction Machine

- High quality: The pomegranate seed extraction machine operates without squeezing or damaging the fruit berries. This ensures the integrity of the pomegranate berries.

- High efficiency: The pomegranate peeling machine can process 1-5 tons of pomegranates per hour. This provides a guarantee for subsequent processing.

Impurity Vibration Removal Machine

- Clean: Impurities and pomegranate seeds are discharged from separate outlets. A water flow cleanses the pomegranate seed channel, ensuring their cleanliness.

- Gentle: Impurities are removed through vibration. Pomegranate seeds fall through the screen. They are then rinsed by water flow to the next processing line. The process does not damage the pomegranate seeds.

Frozen Pomegranate Arils Processing Machine

- Reduce costs: The frozen pomegranate arils processing machine can complete the quick-freezing process in just half an hour. This results in high efficiency and high output, reducing production costs per unit time.

- Improve appearance: The frozen pomegranate arils processing machine freezes quickly. The resulting small ice crystals do not damage the pomegranate cell structure. Frozen pomegranate arils have a good texture and remain separate without sticking together.

Automatic Pomegranate Aril Peeling Separator Machine

Fruit Iqf Fluidization Fluidized Quick Freezing Process Machine

Optical Pomegranate Grapefruit Sorting Equipment 1-10t/H

Frozen Pomegranate Arils Processing Machine Advantages

- Cost Reduction: The IQF pomegranate arils processing line is highly automated. The entire line can replace dozens of workers, reducing labor costs.

- Patented Technology: The pomegranate washing and peeling line solves the seed extraction problem. Provides raw material security for pomegranate deep processing.

- Safety: The IQF pomegranate arils processing line is made of food-grade stainless steel. The equipment has no unsanitary corners, and daily cleaning and maintenance are simple. It meets international food safety and export certification requirements such as HACCP and FDA.

- Enhanced Competitiveness: Quick-frozen pomegranate seeds have a bright color and delicious taste. Consistent quality enhances its appeal to international customers and the high-end retail market.

- Long Shelf Life: Frozen pomegranate arils can be stored for 18–24 months at temperatures below -18°C. Suitable for global distribution and inventory management, increasing business revenue.

- Customization: The IQF pomegranate arils processing line can also be paired with a pomegranate sorting machine or a color protection process. Gelgoog provides customized production line configurations according to customer needs. Submit the form below to customize!

Leave A Message For A Quote