Fruit Freeze Drying Machine Feature

- Fully Automated Operation: Commercial fruit freeze dryer utilizes a PLC control system. The temperature, vacuum level, and processing time can be adjusted with a single click.Reduced manual intervention.Easy operation optimizes production efficiency.

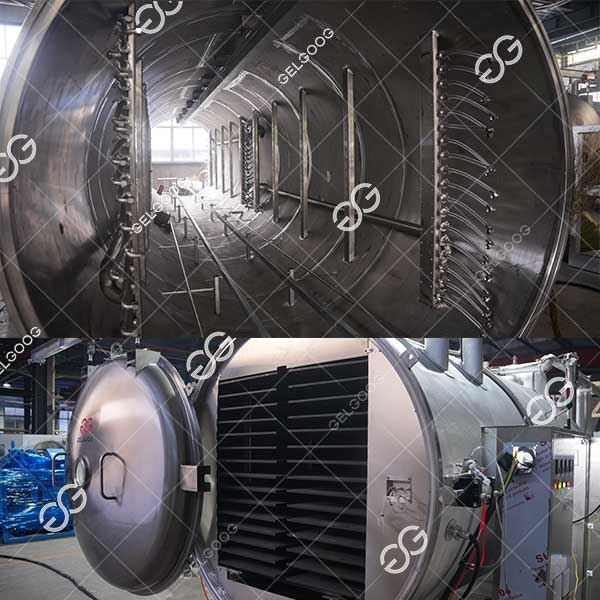

- Safe and Durable: This fruit freeze dryer is constructed of SUS304.The material is highly corrosion-resistant.Safe and durable, ensuring long-term stable operation.

- High Product Quality: This fruit freeze dryer utilizes vacuum freeze-drying technology.The fruit’s flavor, nutrients, and color are well preserved.The resulting crisp texture enhances product value.

- Energy-Friendly: This commercial fruit freeze dryer is equipped with a heat recovery system.Reduced energy consumption meets the requirements of green and energy-saving production.

- Multi-Purpose: This freeze dryer is suitable not only for fruits and vegetables, but also for medicinal herbs, seafood, coffee, and other products.

- Healthy and additive-free: Freeze-dried fruit has an extremely low moisture content and a long shelf life. No preservatives are required and it can be stored at room temperature. It is a natural and healthy food.

Fruit Freeze Drying Machine Work Principle

The core principle of a fruit freeze dryer is sublimation. The water in the fruit is converted directly from solid (ice) to gas (water vapor), skipping the liquid phase. The working principle of a commercial fruit freeze dryer machine is based on two core technologies: low-temperature freezing and vacuum dehydration:

- Pretreatment and quick freezing: Fresh fruit is carefully selected, cleaned, peeled, and pitted. It is then cut and sliced according to product requirements. The processed fruit is then transported to the freeze drying chamber. The temperature is rapidly lowered to below the eutectic point (typically -30°C to -50°C) within a short period of time. The purpose of this rapid freezing is to cause the water within the fruit cells to form tiny ice crystals.This prevents larger ice crystals from piercing the cell walls.

- Vacuum: Once the fruit is completely frozen solid, a vacuum pump reduces the air pressure in the freeze drying chamber to an extremely low level (typically tens of Pascals). This vacuum causes the triple point of water to change, creating the physical conditions for ice sublimation.

- Sublimation heat generation: The fruit freeze drying machine uses heating plates to provide controlled, gentle heat to the fruit. After absorbing this heat, the ice crystals sublime directly from a solid state into water vapor. Because the vacuum inside the chamber allows this water vapor to escape unimpeded.

- Water Vapor Capture: The sublimated water vapor flows to the extremely cold condenser (water trap). There, it recondenses as frost on the condenser’s surface. This continuously separates and captures water from the fruit.

- Rehydration: After the ice crystals sublime, a porous, sponge-like structure forms within the fruit. The fruit’s volume remains largely unchanged, and upon rehydration, it returns to its original shape.

Gelgoog Fruit Freeze Drying Machine Advantage

- Unique Crisp Texture: The honeycomb-like porous structure delivers an unprecedented crispy texture, beloved by consumers of all ages.

- High Value-Added: The unit price of freeze-dried fruit is significantly higher than that of fresh and dried fruit.High product profit margins.

- The fruit freeze dryer machine maximizes the preservation of nutrients in fruits and vegetables.This includes vitamins, minerals, dietary fiber, and more.It eliminates the nutrient loss associated with traditional drying.

- Reduced Transportation Costs: Freeze-dried fruit is lightweight.This significantly reduces packaging, transportation, and storage costs.

- Customizable: The fruit freeze dryer machine can be combined with a fruit washer, peeler, and cutter. We can customize fruit processing solutions based on your plant layout and production requirements.

- Innovation and R&D: Gelgoog is committed to innovation and keeps pace with industry trends. We continuously optimize equipment performance to provide more efficient and energy-saving solutions.

- Comprehensive Service: We offer one-stop services, from site planning, installation and commissioning, operator training, and maintenance. Some areas have resident engineers who are ready to solve equipment problems at any time.

Fruit Freeze Drying Machine Application

- Food Processing: Freeze-drying fruits, vegetables, and preserved fruits for snack, beverage, and jam production lines.

- Healthy and Nutritious Foods: Suitable for nutritional supplements, baby food, sports food, and other health industries, preserving nutrients.

- Pharmaceutical Industry: Freeze-drying medicinal herbs to ensure the loss of active ingredients.

- Coffee and Tea Processing: Freeze-drying coffee and tea ingredients to preserve their natural aroma and taste.

- Seafood and Meat Processing: Freeze-drying seafood and meat products for convenient storage and transportation, meeting the needs of modern fast food and ready-to-eat meals.

Leave A Message For A Quote

Reviews

There are no reviews yet.