Iqf Freezing Process Features

- High-speed cooling: iqf fluidization freezer’s compressor can cool the fruit to -30℃ to -40℃ within 30 minutes. This prevents the formation of large ice crystals and preserves the fruit’s structure. It meets IQF (Individually Quick Freezing) technical requirements.

- IQF technology: iqf freezing process ensures that fruit (whole fruit, slices, or cubes) remains separated in the freezing tunnel. Whether whole or diced/sliced, each piece freezes independently without sticking or clumping.

- Intelligent control system: PLC touchscreen control enables automatic temperature control and operation monitoring.iqf fluidization freezer’s conveyor belt operates smoothly and can adapt to different freezing time requirements.

- Safe materials: Fluidized quick-freezing machine uses a SUS304/316 food-grade stainless steel conveyor belt. The surface is smooth, allowing materials to freeze directly on the belt.

- Insulated chamber: Iqf fluidization freezer’s chamber uses 120mm thick polyurethane insulation panels. Double-layered SUS304 stainless steel inside and out, it offers excellent insulation performance. It is equipped with an inspection door for easy cleaning and maintenance of iqf freezing process.

Iqf Freezing Process Work Principle

- Pre-cooling: Fruit needs to be pre-cooled before entering iqf fluidization freezer. The fruit temperature should not exceed 15℃ to ensure the freezing capacity and freezing time of the machine.

- Flowing: Pre-cooled fruit enters the freezing zone evenly via a conveyor belt. A cold air blower cools the air to -35℃ to -40℃ through an evaporator. Strong cold air is sprayed upwards through stainless steel ducts at the bottom. The airflow passes through the fruit, lifting it and creating a “fluidized” state.

- Quick Freezing: In a suspended state, all surfaces of the fruit are simultaneously and evenly cooled by the cold air. fluidized quick-freezing machine freezes quickly and prevents sticking. The core temperature of the fruit can be reduced to below -18℃ within 8-30 minutes.

- Discharge: A lifting conveyor is located at the other end of iqf fluidization freezer. This quickly transports the frozen product out of the freezer for packaging or refrigeration.

Iqf Freezing Process Advantages

- Freshness Preservation: The iqf freezing process minimizes the damage to cell structure caused by ice crystals.It preserves the fruit’s flavor and nutrients. Frozen fruit can be stored at -18°C or lower for 12–24 months or longer.

- Energy Saving and Environmental Protection: Iqf fluidization freezer features an insulated storage design, reducing refrigeration energy consumption by 15–20%. A water-circulating defrosting system extends operating cycles and reduces defrosting frequency.

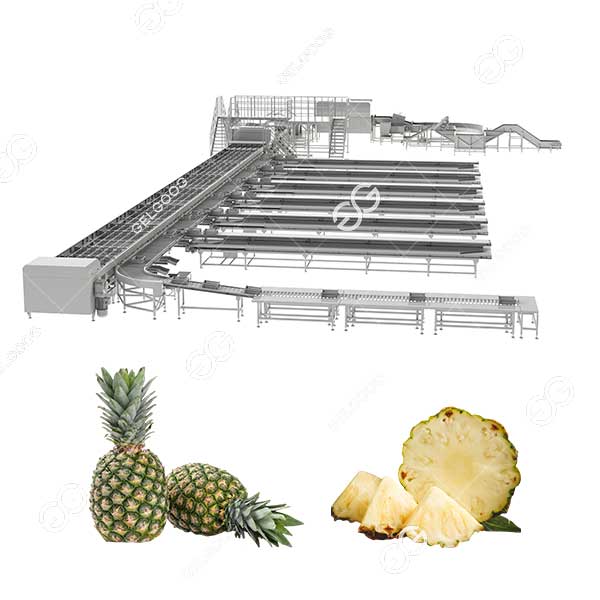

- Supports Multiple Fruit Types: Iqf freezing process is suitable not only for fruits such as strawberries, blueberries, cherries, bananas, pineapples, and mangoes, but also for freezing vegetables, root vegetables, and nuts.

- Improved Finished Product Quality: The fruit quick freezer uses individual quick-freezing to prevent fruit from sticking together, improving finished product quality.

- One-Stop Service: Fluidized quick-freezing machine can be paired with washing machines, cutting machines, and packaging machines. Gelgoog provides fruit processing solutions, helping you build a complete cold chain processing line.

Technical Data

| Model | Power | Size |

| DS100 | 5KW | 5300*2500*2500 |

| DS200 | 8.2KW | 6700*2700*2500 |

| DS300 | 11.2KW | 7900*3300*2500 |

| DS500 | 20KW | 8200*4200*3200 |

| DS1500 | 50KW | 14200*4200*3300 |

| DS2000 | 72KW | 17700*4200*3300 |

Reviews

There are no reviews yet.