Mango Dehydrator Machine Features

- Precise and Intelligent Temperature Control: The dried mango processing machine features an intelligent touchscreen control system for easy operation. Drying temperatures are accurate to ±1°C. Up to 20 programmable temperature and humidity curves are supported to meet the needs of different mango varieties.

- Environmentally Friendly: The mango dehydrator machine is equipped with an intelligent dehumidification and heat recovery system. This system removes moisture while recovering waste heat, significantly reducing energy consumption. The Gelgoog mango drying machine manufacturer ensures zero emissions throughout the drying process, making it a green and environmentally friendly drying method.

- Reduced Production Costs: Conventional drying uses manual temperature control, which requires significant labor and fuel. Commercial mango fruit drying machines utilize an automatic temperature control system. The mango dehydrator machine’s preset drying process curve eliminates the need for manual intervention. One person can manage multiple drying rooms simultaneously, saving labor costs.

- Improved Product Quality: Conventional drying uses manual control of combustion calorific value and drying temperature. Drying quality is easily affected by operator experience. The mango dehydrator machine utilizes intelligent control to ensure high-quality drying.

- Higher Production Efficiency: Mango drying machine allows for efficient drying and dehumidification in separate stages. Save drying time and costs.

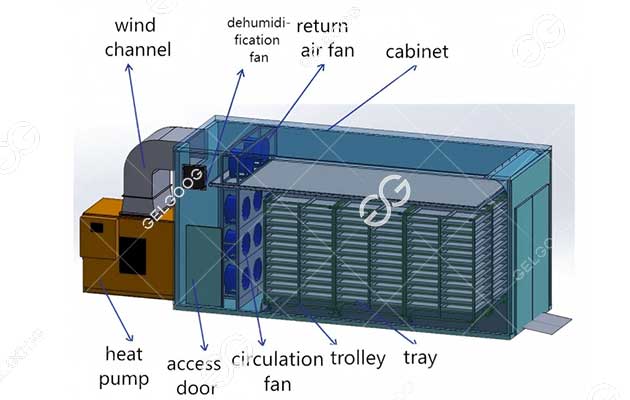

Mango Dehydrator Machine Principle

The core operating principle of a commercial mango drying machine is similar to air conditioning heating, a process of energy transfer and enhancement:

- Heat absorption: The refrigerant absorbs cool air from the ambient air in the evaporator.

- Compression and heating: The compressor consumes a small amount of electrical energy to compress the low-temperature, low-pressure refrigerant gas into a high-temperature, high-pressure gas.

- Exothermic drying: The high-temperature, high-pressure refrigerant liquefies in the condenser, releasing a large amount of high-temperature heat. This heat is forced and evenly blown into the drying room by a circulating fan, heating the mangoes and evaporating their internal moisture.

- Intelligent dehumidification: The hot, humid air, which contains a large amount of moisture, passes through the dehumidification heat recovery unit. The heat is recovered and the moisture is condensed and discharged outdoors.This achieves a highly efficient and energy-saving dehumidification process.

Mango Dehydrator Machine Suitable For

- Agricultural products: Shiitake mushrooms, wood ear mushrooms, chili peppers, wolfberries, etc.

- Traditional Chinese medicine: Moringa leaves, honeysuckle, Panax notoginseng, ginseng, wolfberries, Gastrodia elata, etc.

- Food processing: Seafood, dried fruits and vegetables, etc.

Mango Dehydrator Machine Advantage

- Versatile: The mango drying machine can also be used to dry fruits such as pineapples, bananas, and papayas.

- Safe and Durable: The mango drying machine manufacturer uses 75mm thick polyurethane hook panels for the housing. The cart is made of 304 stainless steel, and the tray is made of PP. It’s easy to install and provides excellent heat retention.

- High Product Quality: Dried mangoes are a natural golden color with no browning.

- Customizable: We have numerous successful cases in Southeast Asia, the Middle East, and South America. We can customize solutions based on your plant layout and production requirements.

- One-Stop Service: Gelgoog also offers equipment for mango washing and grading, peeling and pitting, dicing, and quick-freezing. GELGOOG provides you with a one-stop mango production line solution.

Reviews

There are no reviews yet.