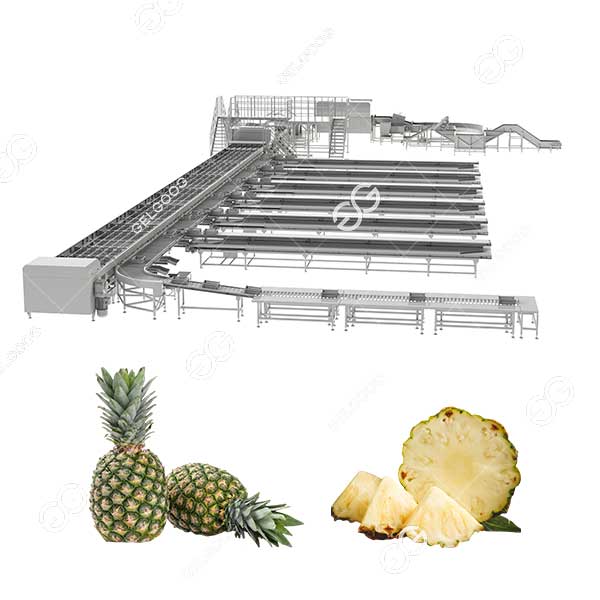

Pineapple Peeling Machine Feature

1. Semi-Automatic Peeling Machine:

- Efficient and Convenient: Peeling and coring are completed in one go.Significantly saves time and costs.

- Clean Processing: The pineapple peeling machine directly removes the pineapple skin, ensuring pulp quality.

- Improved Production Efficiency: Manual pineapple peeling takes a long time. The pineapple peeling and coring machine can process 12 pineapples per minute.

- Reduced Labor Costs: Manual peeling requires several workers simultaneously. The commercial pineapple corer only requires one worker to cut the pineapple skin and one to operate the machine.Reduced Labor Costs.

2. Automatic Peeling Machine:

- Highly Automated: Place the pineapple in the commercial pineapple corer, and the entire process is automated. The precision cutting system seamlessly removes the skin and core. No manual intervention is required.

- Infrared Assist System: The feed port features infrared positioning to accurately position the pineapple.Enabling a smooth, single-cut cut.

- Improved food safety: After removing the pineapple leaves, the peeling process is contactless.Reduced bacterial exposure improves food safety.

- Improved production efficiency: The Gelgoog commercial pineapple corer can meet 24/7 continuous industrial production.

- Simple and adjustable operation: The pineapple peeling and coring machine can adjust the peeling thickness and force according to the size and ripeness of the product.Minimizes fruit waste.

Pineapple Peeling Machine Work Principle

Semi-Automatic Peeling Machine

- Pre-processed (head and tail removed) pineapples are manually placed on an adjustable feed rack. The center height is adjusted to maintain the optimal position between the pineapple and the cutting system. The pneumatic system then operates, steadily pushing the pineapple forward.

- The pineapple is pushed into the high-speed rotating peeling drum (adjustable speed). The peeling knives, acting through a combination of centrifugal force and propulsion, remove the pineapple’s outer skin. Simultaneously, a corer inside the feed bar advances synchronously, completely removing the pineapple’s hard core.

- The finished cylindrical pineapple can is discharged from the outlet. The skin and core are collected separately through dedicated channels, ensuring full utilization of the raw material.

- The pineapple peeling and coring machine uses a large cutting pattern to quickly remove the skin. For higher-quality pineapple pulp, it can be used in conjunction with a pineapple cutting machine.

Automatic Peeling Machine:

- Place the pineapple, after removing the petiole, at the inlet. Ensure the center is aligned with the infrared beam.

- The pineapple passes through the pineapple peeling and coring machine and enters the first cutting disc for peeling.

- After the first peeling, the pineapple’s base is trimmed. It then enters the second cutting disc.The second cutting disc removes the core and stem, preserving as much flesh as possible.

- The finished pineapple cone is transported out of the machine for the next step of processing.

Pineapple Peeling Machine Advantage

- Hygienic Design: The commercial pineapple corer is made of stainless steel, meeting food processing standards and easy to clean and maintain.

- Safe and Reliable: The pineapple peeling machine’s high-strength blade design prevents damage to the pineapple flesh.Ensures the appearance and quality of your food.

- Adaptable: The pineapple peeling and coring machine is suitable for pineapples of varying sizes and maturity.It solves the problem of incomplete peeling caused by uneven peeling.(We also have a pineapple grading machine. It can grade pineapples according to maturity, sugar content, size, and weight.)

- Advanced Technology: Gelgoog has many years of experience in the research and development of fruit and vegetable processing equipment, resulting in mature technology and stable product quality.

- Customized Service: Gelgoog can provide customized solutions based on your needs.

- Full Service: We provide comprehensive services from equipment selection, installation and commissioning to after-sales maintenance and technical support.Ensure smooth production operations for our customers.

- Cost-effective: We provide high-quality equipment and technical services while ensuring cost-effectiveness.Helping our customers reduce production costs and improve profitability.

Pineapple Peeling Machine Suitable For

1. Pineapple Canning Plant

Can provide a continuous and stable supply of standardized pineapple cans.Ensures uniform canned product specifications and improves production line automation.

2. Fresh-Cut Fruit Processing Plant

Produces smooth, high-quality fresh-cut pineapple products through secondary processing.Meets high-end market demands.

3. Catering Supply Chain

Provides standardized pineapple ingredients to catering companies, reducing back-of-house pre-processing steps.Improves food delivery efficiency.

4. Fruit Deep-Processing Plant

Provides high-quality raw materials for deep-processed products such as pineapple juice and dried pineapple.Ensures consistent product quality.

Technical Data

|

Semi-Automatic Peeling Machine |

|

| Processing Capacity | 6-12pieces/minute |

| Applicable Specifications | Pineapple Outer Diameter Φ100-130mm |

| Power | 0.75KW |

| Size | 1200×700×1300mm |

| Number of Blades | 4 |

Reviews

There are no reviews yet.