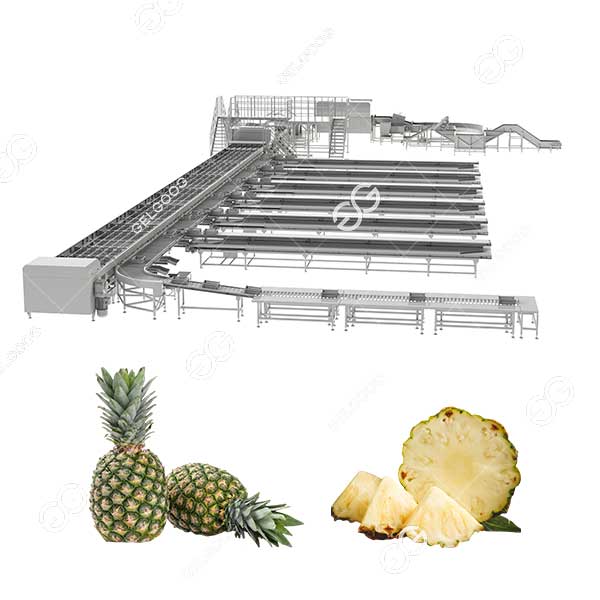

Pineapple Washing Machine Features

- Thorough Cleaning: The pineapple fruit washing machine is equipped with multiple brush rollers.It also features a high-pressure spray nozzle on top, ensuring a thorough cleaning of every corner.

- Versatile: Commercial pineapple washing machine is not only suitable for pineapples, but can also clean hard-skinned fruits such as avocados, papayas, coconuts, and oranges.

- High-Quality Materials, Durable: The pineapple cleaning machine is made of food-grade 304 stainless steel. It is corrosion-resistant, has a long lifespan, and meets food safety standards. It is easy to disassemble and maintain.

- Water and Energy Saving: Pineapple fruit washing machine features a built-in water recycling and filtration system. This recycles water, reducing water costs.

- Easy Operation: Pineapple cleaning machine is equipped with a PLC intelligent touchscreen control system. Parameters such as conveyor speed and water pressure can be easily adjusted for simple operation.

Pineapple Washing Machine Work Principle

- Soaking and Sorting: First, soak the pineapples in the pineapple washing machine’s tank. This not only pre-washes the pineapples but also sorts out any bad fruit that sinks to the bottom. The selected good fruit are then smoothly transported to the washing tank via an elevator or conveyor belt.

- High-Pressure Spray Cleaning: Multiple rows of stainless steel nozzles are installed at the entrance of the pineapple cleaning machine. These spray high-pressure water mist from various angles, washing away large particles of sand and impurities from the pineapple’s surface.

- Deep Abrasive Cleaning with a Brush Roller: This is the core process of the entire machine. The washing tank of the pineapple fruit washing machine is equipped with a nylon brush roller. As the pineapple moves across the brush roller, the brushes adhere closely to the pineapple’s rough, uneven skin. The mechanical friction of the brushes effectively removes dirt from the crevices of the pineapple’s skin.

- Automatic Drainage: During the washing process, the high-pressure spray head on the top of the commercial pineapple washing machine flushes away dirt. The cleaned silt and impurities are discharged through a drain outlet at the bottom. Pineapple cleaning machine maintains constant clean water quality, ensuring continuous operation.

- Discharging and Air Drying: Thoroughly cleaned pineapples are discharged via a stainless steel mesh belt. Customers can choose Gelgoog air drying machine, cuttinfg machine, quick freezing machine, or packaging machine based on their subsequent processing needs.

Gelgoog Pineapple Washing Machine Advantages

- Customizable Equipment: Gelgoog can customize your pineapple cleaning machine based on your plant layout and production requirements.

- Full-Service: We provide one-stop services, from site planning, installation and commissioning, operator training, and maintenance. Resident engineers are available in select locations to address equipment issues promptly.

- Energy-Efficient: Commercial pineapple washing machine can process 1 ton of pineapples per hour. It significantly improves production efficiency and reduces labor costs.

- Integrated Equipment: The pineapple washing machine can be integrated with cutting machines, freezing machines, packing machines, and other equipment. Gelgoog offers a complete pineapple processing line.

Technical Data

|

Model |

Production capacity | Power |

Size |

| XM800 | 400KG | 1.1KW | 1600*850*800mm |

| XM1000 | 600KG | 1.5KW | 1800*850*800mm |

| XM1200 | 800KG | 1.5KW | 2000*850*800mm |

| XM1500 | 1000KG | 2.2KW | 2300*850*800mm |

| XM2000 | 1500KG | 3KW | 2800*850*800mm |

| XM2600 | 2000KG | 4.75KW | 3100*850*1450 mm |

Reviews

There are no reviews yet.