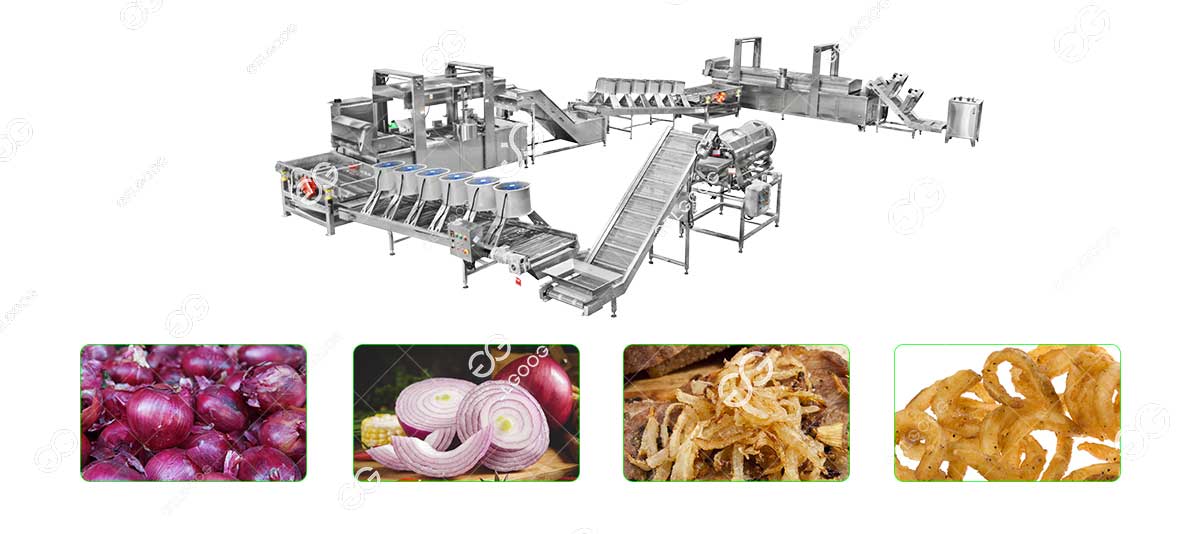

Fried Crispy Onion Production Frying Line

Fried onions have strong demand in the snack and food ingredient markets.However, achieving large-scale production of fried onions with uniform shape and excellent flavor faces many challenges.The gelgoog fried crispy onion production line is designed for efficient and stable production. It integrates precise cutting, even coating, and gentle frying processes, providing a one-stop solution from raw onions to finished product.

Onion Frying Line Flow Chart

Feeding → Peeling & Slicing → Shredding/Chopping → Coating with Flour → Frying → Degreasing → Cooling → Seasoning → Packaging

- Sorting:Select premium onions, removing diseased, damaged, and substandard ones.

- Peeling & Slicing: Remove the outer skin of the onion. Trim the root end.

- Chopping: Slice or ring the onion according to the desired product.

- Coating with Flour: This process can be added upon customer request. Flour coating ensures a golden, crispy exterior and a rich, layered texture.

- Frying: Continuous frying line, quickly frying at a constant oil temperature until golden brown and set.

- Degreasing: Remove excess oil to achieve a clean, non-greasy texture.

- Seasoning: Use a drum or vibrating seasoning machine to evenly coat the onions with seasoning.

- Packaging: Multiple packaging options available.

Commercial Onion Frying Machine

Onion Washing Machine

- Gentle yet effective: Washes onions without damaging their skin.

- Adjustable: Washing speed and pressure are adjustable. Suitable for onions of various qualities.

Onion Cutting Machine

- High efficiency: The onion cutting machine allows for adjustable cutting thickness and speed. It can cut 100-1000 kg of onions per hour.

- High quality: Onions cut by the onion cutting machine have smooth cuts and minimal breakage.

Onion frying machine

- Frying methods are optional: Gelgoog offers both gas-powered and electric frying machines.

- Intelligent: The onion frying machine features precise temperature control. Frying at a constant temperature until all moisture evaporates results in golden-brown fried onions.

Fruit And Vegetable Washing Machines

Industrial Cabbage Washing Machine For Brussels Sprouts Palm Core

Rated 0 out of 5

Fruit and Vegetable Cutting Machines Supplier

Vegetable Cube Cutting Machine For Potato Carrot Oinon Dicer

Rated 0 out of 5

Onion Frying Line Advantages

- Automation: The entire onion frying line operates automatically, reducing manual operation and labor costs. It also improves production efficiency and consistency.

- High Quality: The onion cutting machine allows for customized slicing/ring thickness and size. Gelgog offers various seasoning processes to meet diverse market and product needs.

- Robust and Durable: The onion frying machine is made of food-grade stainless steel. It is corrosion-resistant, easy to clean, and has a long service life.

- Energy Saving: The onion frying line is equipped with an oil circulation filtration system and an automatic slag removal system. Stable temperature control reduces operating costs.

- Versatile: The onion production line can also process potatoes, bananas, cassava, and other raw materials.

- Comprehensive Service: We provide a one-stop service from site planning, installation and commissioning, operation training to maintenance.

Leave A Message For A Quote