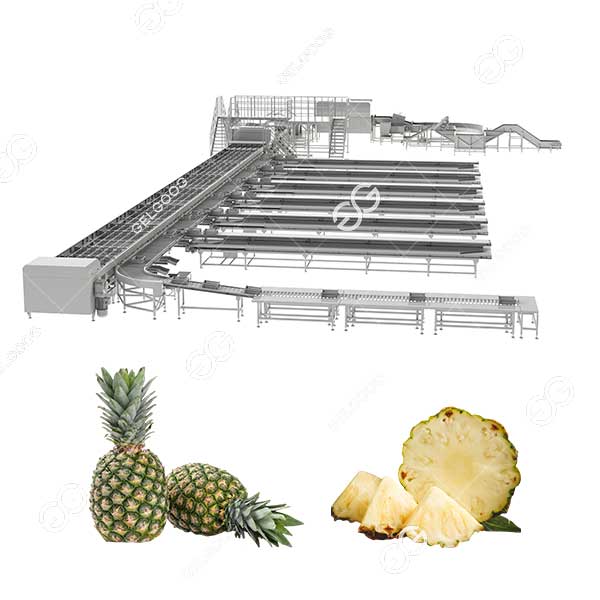

Pineapple Juice Production Line From Washing To Filling

Pineapple juice, with its unique tropical flavor and rich nutrients, is highly favored in the global juice market. Gelgoog automatic pineapple juice production line is specifically designed for large-scale, high-efficiency pineapple juice production.

This pineapple juice processing machine line features efficient peeling and core removal technology, as well as advanced pressing, filtration, and aseptic filling technologies. It maximizes juice yield while preserving the natural flavor and vitamins of the pineapple. With its high degree of automation, the pineapple juice production line is an ideal industrial solution for juice factories, beverage companies, and food processing plants.

Pineapple Juice Processing Flow Chart

Feeding → Stem Removal → Washing → Juicing → Coarse Filtration → Fine Filtration → Sterilization → Concentration → Deaeration → Filling

- Feeding: Pineapples are transported to the processing area using AGV technology.

- Stem Removal: The pineapple stem is removed for easier subsequent processing.

- Washing: A combination of brush cleaning and bubble cleaning machines ensures a clean pineapple surface.

- Juicing: The pineapple enters the pineapple juice making machine. Peel, pulp, and juice are discharged through different channels.

- Filtration: Multiple filtration machines can be used depending on customer requirements.Ensuring the purity of the pineapple juice.

- Sterilization: The pineapple juice is sterilized. This improves product safety and shelf life.

- Concentration: Water is evaporated under low temperature and low pressure to obtain concentrated pineapple juice.

- Deaeration: Prevents oxidation of the pineapple juice. Preserves the color and flavor of the pineapple juice.

- Filling: Gelgoog juice filling machine automatically completes filling, capping, and labeling.

Pineapple Jucie Making Machine

Pineapple Washing Machine

- Multiple Options: Gelgoog offers a variety of pineapple washing machines, including brushing, bubble, and vortex types. Customers can choose the appropriate machine based on the pineapple’s texture. Brushing and bubble washing machines can also be used together to thoroughly clean the pineapple peel.

- Environmentally Friendly: The pineapple washing machine is equipped with a water circulation system, allowing filtered water to be recycled.

Pineapple Juice Making Machine

- High Quality: The pineapple juice making machine boasts a high juicing rate. It maximizes the amount of juice obtained from a single unit of raw material, improving economic efficiency.

- Filtration: The pineapple juice making machine can coarsely filter out pineapple peels and pulp. The pulp and pineapple juice are discharged through separate channels, simplifying waste management.

Pineapple Jucie Filling Machine

- Automation: The gelgoog juice filling machine is highly automated. It can automatically transport and clean bottles, perform quantitative filling, capping, and labeling.

- High Quality: The gelgoog juice botting machine allows for user-set filling volume. The filling process is leak-free, ensuring cleanliness. The filling volume is consistent, with minimal error per bottle.

Pineapple Fruit Sorting Grading Machine 1-10 Tons Manufacturer

Pineapple Juice Production Line Advantages

- Intelligent Control: The pineapple juice processing machine line is equipped with a PLC intelligent control system. Cleaning intensity, speed, and angle are freely adjustable. Filling volume and speed are also freely adjustable.

- Reduced Costs: The pineapple juice production line operates fully automatically, requiring only 1-2 people to operate. This significantly reduces factory labor costs.

- High Capacity: The pineapple juice processing machine line can process 500-3000 kg of pineapple per hour. (Larger capacity can be customized upon request.) Suitable for large processing plants such as juice beverage processing plants and fruit and vegetable deep processing enterprises.

- Multi-functional: The pineapple juice production line can also be used to process mango juice, strawberry juice, tomato juice, etc. By combining different machines, it can form NFC juice, concentrated juice, and fruit pulp beverage production lines. High equipment utilization and high return on investment.

- Safety: The pineapple juice processing machine line is made of food-grade stainless steel. It meets international food safety certification requirements such as HACCP. The quick-release structure design facilitates daily cleaning and maintenance.

- One-stop service: Gelgoog provides initial production line planning and factory layout design. We also offer support for later installation, commissioning, personnel training, and after-sales technical assistance. We provide comprehensive service guarantees to ensure smooth project launch.

Leave A Message For A Quote