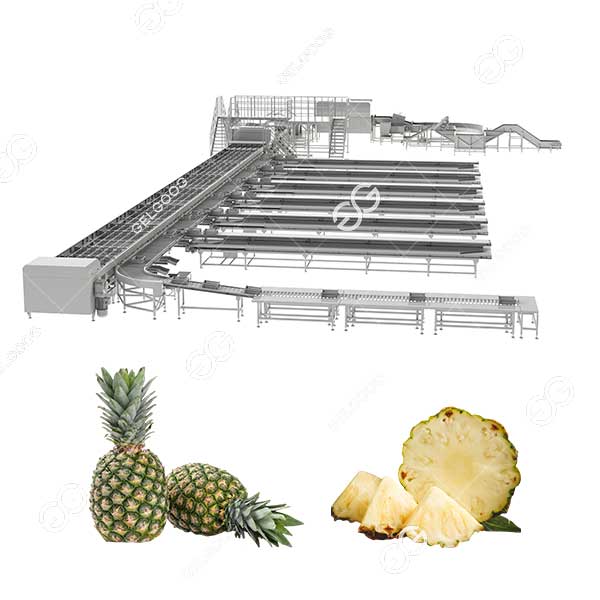

Pineapple Sorting Grading Washing Line Manufacturer

The appearance and internal texture of a pineapple are key factors in determining its price. The Gelgoog pineapple sorting machine can grade pineapples based on their appearance, sweetness, and weight. Combined with a pineapple washing machine and waxing machine, it forms a complete pineapple processing line. Gelgoog provides customized, automated, efficient, and standardized solutions to help your pineapples enter the high-end market.

Pineapple Sorting Line Flow Chart

Feeding → Sorting → Visual Grading → Internal Quality Grading → Weight Grading → Washing → Waxing → Drying → Discharging → Packaging

- Feeding: Pineapples are accurately fed into fruit trays via the sorting equipment. Only one pineapple is placed on each tray, ensuring accurate grading.

- Visual Grading: The pineapple sorting machine takes photos of the pineapple’s appearance. These photos are compared with pre-uploaded images. Pineapples with blemishes, mold, or uneven coloring are discarded.

- Internal Quality Grading: The pineapple sorting line exposes the pineapples to light to obtain a spectrum. This spectrum reflects the pineapple’s sweetness and ripeness and is recorded in the computer.

- Weight Grading: Two scales are installed under each tray for weighing and grading the pineapples.

- Washing: After grading, the pineapples best suited for retail are washed, waxed, and packaged.

- Discharging: Pineapples unsuitable for direct sale are sent to different processing lines, such as dried pineapple or pineapple juice.

Pineapple Processing Line Machines

Pineapple Washing Machine

- Thorough Cleaning: The fruit cleaning machine can scrub the crevices of the pineapple peel, thoroughly cleaning the pineapple.

- Flexibility: The washing power, duration, and water volume of the pineapple processing line machine are adjustable. It can adapt to different batches and the condition of the pineapple peels.

- Environmentally Friendly: The fruit washing machine is equipped with a water recycling system. Wastewater can be filtered and reused, reducing water costs.

Pineapple Sorting Machine

- High Quality: The pineapple sorting line boasts high grading accuracy and speed.Suitable for exporters or processors with large-volume production and strict pineapple specification requirements.

- Customization: Grading standards can be freely set. Customers can customize grading standards based on their needs, including weight, appearance, and internal quality.

- Automation: The pineapple sorting line is simple to operate and highly automated. The grading process requires no manual intervention, reducing labor costs.

- Continuity: The pineapple sorting machine is equipped with air conditioning for cooling. This ensures continuous operation and suits large-scale continuous production.

Fruit And Vegetable Peeling Equipment

Commercial Pineapple Peeling And Coring Machine

Rated 0 out of 5

Fruit Grading Equipment Manufacturer

Pineapple Fruit Sorting Grading Machine 1-10 Tons Manufacturer

Rated 0 out of 5

Pineapple Sorting Line Advantages

- Safety: The pineapple sorting line is made of food-grade stainless steel, meeting food safety standards.

- Customization: Gelgoog supports customization of pineapple sorting machines based on pineapple variety, fruit size, and production capacity requirements. This ensures the pineapple flesh is not damaged, and that cleaning is thorough and grading is precise.

- High Quality: Gelgoog has served over 180 countries worldwide and holds over 300 patents. Gelgoog pineapple sorting line far surpasses the quality of similar products on the market.

- One-Stop Service: We provide a full-process service from solution design, equipment manufacturing, factory layout, installation and commissioning, operation training to after-sales maintenance.

- Standardization: Precise grading ensures uniform pineapple specifications, facilitating access to high-end markets and increasing business profits.

Leave A Message For A Quote